Interview with Nils Sauerborn | Director, Offshore Solutions

Whether onshore or offshore—given the rapidly growing global demand for energy, high-voltage cables are today more essential than ever for the global energy infrastructure as well as the energy transition. Without them, urgently needed electricity simply doesn’t flow. That’s why global cable transportation plays a vital role in ensuring a safe and sustainable power supply. All the more reason for an interview with deugro’s cable experts, whose daily work revolves around planning and executing complex, global cable transport operations—both onshore and offshore.

Hi Nils, thanks a lot for taking the time for this interview. Could you briefly introduce yourself and explain your connection to cables?

I lead the Global Wind Renewable Energy’s (GWRE) Cables vertical at deugro, which focuses on high-voltage cable logistics for both onshore and offshore projects. My background is in offshore wind energy and global project logistics, and cables have been part of my work for many years. It’s a specialist field, but it’s also central to connecting renewable energy from the power generation into your home power socket—something we work with daily in the GWRE division.

What exactly are your responsibilities in relation to cables, and what services do you offer your clients in this field?

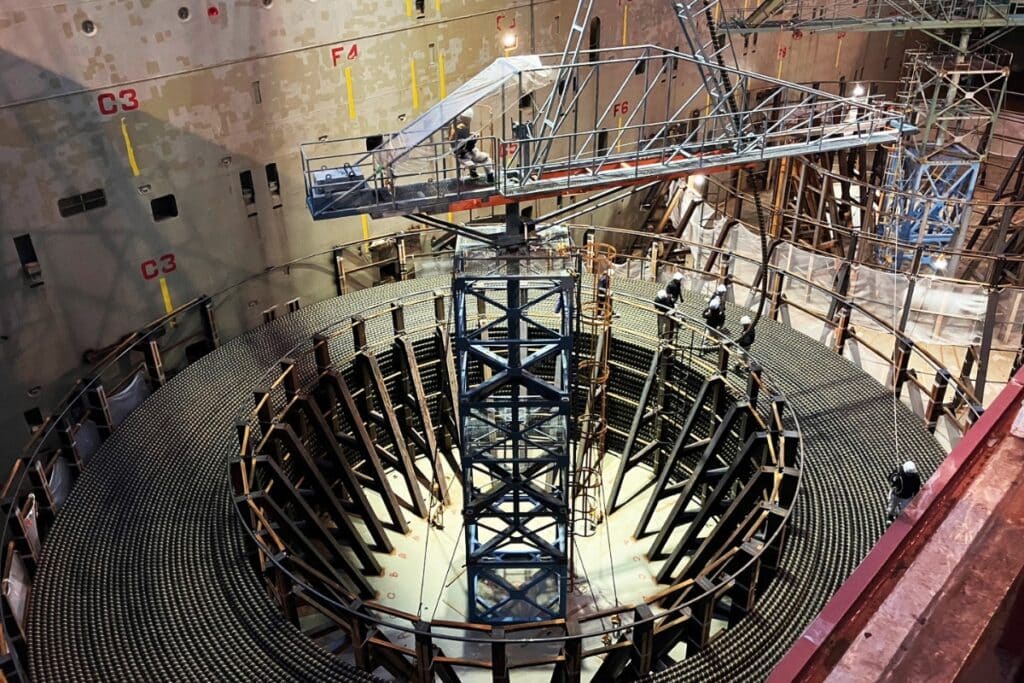

We manage end-to-end cable transports: planning, execution and everything in between. This can include securing specialized vessels, designing and installing spooling equipment, and coordinating port and inland operations. Our projects are global, and our GWRE team brings together expertise from across regions to deliver the right solutions for each client. Alongside the Cables and Transmission Solutions verticals, GWRE has dedicated verticals for Wind Chartering, Wind Turbines, Foundations, and Operations & Maintenance, which means we can support clients through every stage and every component of a renewable energy project, not just the cables.

Cables are the lifeline for electricity transmission—be it to substations or to end consumers. Without them, the entire infrastructure—from energy generation and conversion to distribution and usage—cannot be fully commissioned or operated. What does this mean for the logistical planning and execution of such cable projects and transports?

It means precision is non-negotiable. Without cables, projects can’t produce or transmit power, so any delay has an immediate impact and withholds the project from being energized. At GWRE, we’re used to working with extremely tight schedules and aligning multiple stakeholders, equipment providers, and routes so everything happens exactly when it needs to. Quality and safety run through every stage.

As one of the world’s leading project logistics providers, deugro has been transporting a wide variety of cables for over 100 years. What has changed since then?

The cables themselves have become bigger, heavier and longer, and the pace of the industry is faster than ever. With the global energy transition, there’s more demand for offshore connections and larger-scale projects. As an example: Just recently a project required the movement of interconnector cables, with a length of approximately 100 kilometers, in one piece, while considering the average weight of about 100 kilograms per meter. GWRE’s role is to adapt quickly—finding equipment and vessel solutions, even when the market is tight, while keeping deliveries on time and compliant.

What are the biggest challenges in onshore and offshore cable projects?

For offshore, it’s often vessel availability, weather windows, and coordinating between countries. Onshore can involve permits, infrastructure limits, or cross-border planning. In both cases, GWRE’s advantage is our network and experience—knowing how to navigate these challenges without losing time.

What are the key requirements for successfully managing cable transports and projects—minimizing risks, and keeping timelines and budgets on track?

Experience and preparation. You need to understand both the cargo and the client’s processes inside out. The GWRE team invests in strong relationships with clients, so we can anticipate needs and adapt solutions—whether that means modifying a carousel, finding a specialized trailer, or securing a port slot at short notice.

Due to their nature, cables have not traditionally been considered typical project cargo, such as individual oversized or heavy-lift plant components or modules. What impact does this have on transport planning and preparation, as well as handling during transport?

They require specialized handling from the moment they’re loaded. This includes expensive assets, such as the transport vessel, carousels, and spooling equipment, but also lifting plans, and storage solutions. GWRE has developed a deep understanding of these requirements, so we can plan operations that are both safe and efficient.

Beyond the standard project logistics portfolio, what additional services do you offer cable clients?

We provide the complete range of solutions: engineering, spooling, installation support, vessel chartering, and all related activities. By managing the entire chain, GWRE ensures cables arrive exactly as required for installation, without the client having to coordinate multiple providers. We are the one-stop shop for the cable industry.

What are the most striking differences between the planning and the executing of onshore and offshore cable transports and projects?

Offshore relies heavily on vessel timing and weather, while onshore is more about navigating infrastructure and permits. GWRE works in both spaces, so we’re able to apply lessons from one to the other and keep projects moving.

Could you tell us about some of the most recent cable-related projects that you delivered or are working on? What were the biggest challenges you faced?

We’ve supported several major cable projects recently, including offshore interconnectors and large onshore HVDC links. Challenges have ranged from equipment shortages to narrow installation windows. In each case, the GWRE team’s planning and global coordination helped to ensure that the cables were delivered on time, ready for installation.

To ensure ongoing cable-laying operations for the Turkish Crossing Project, deugro Italy, in cooperation with deugro Chartering, timely delivered 54 kilometers of urgent HVAC cables to a cable-laying vessel in Turkey.

For the SuedOstLink, one of Germany’s central energy transition projects, deugro currently delivered altogether over 800 cable drums from two storage yards in Kelheim and Regensburg to 120 different job sites across Bavaria, Germany.

As part of the Cyclades IV Interconnector Project, deugro delivered 58 kilometers and 3,550 metric tons of subsea cable from Finland to Heraklion Port on the Island of Crete in Greece.

For keeping ongoing cable-laying operations for an HVDC submarine cable electrification project on track, deugro delivered 700 kilometers of MRC, DC400kV and FO cables, totaling 15,500 metric tons, from Japan and Norway to a cable-laying vessel in Abu Dhabi, UAE.