Petrochemical

Since its foundation in 1924, deugro has been a market leader for customized project logistics and end-to-end supply chain management solutions for the energy and petrochemical industry.

Leading Companies, such as EPCs and OEMs, in the petrochemical industry trust us to design and deliver project logistics for complex petrochemical plants.

Focus areas

- LNG plants and terminals

- Refineries and processing plants

- Polymer and chemical plants

- Revamps andextension

- OSHL Components (reactors, adsorbers, splitters, etc.)

Value proposition

- We deliver comprehensive logistics solutions, from early project engagement and detailed transport planning to the execution of intricate turnkey projects

Industry: Energy and petrochemicals

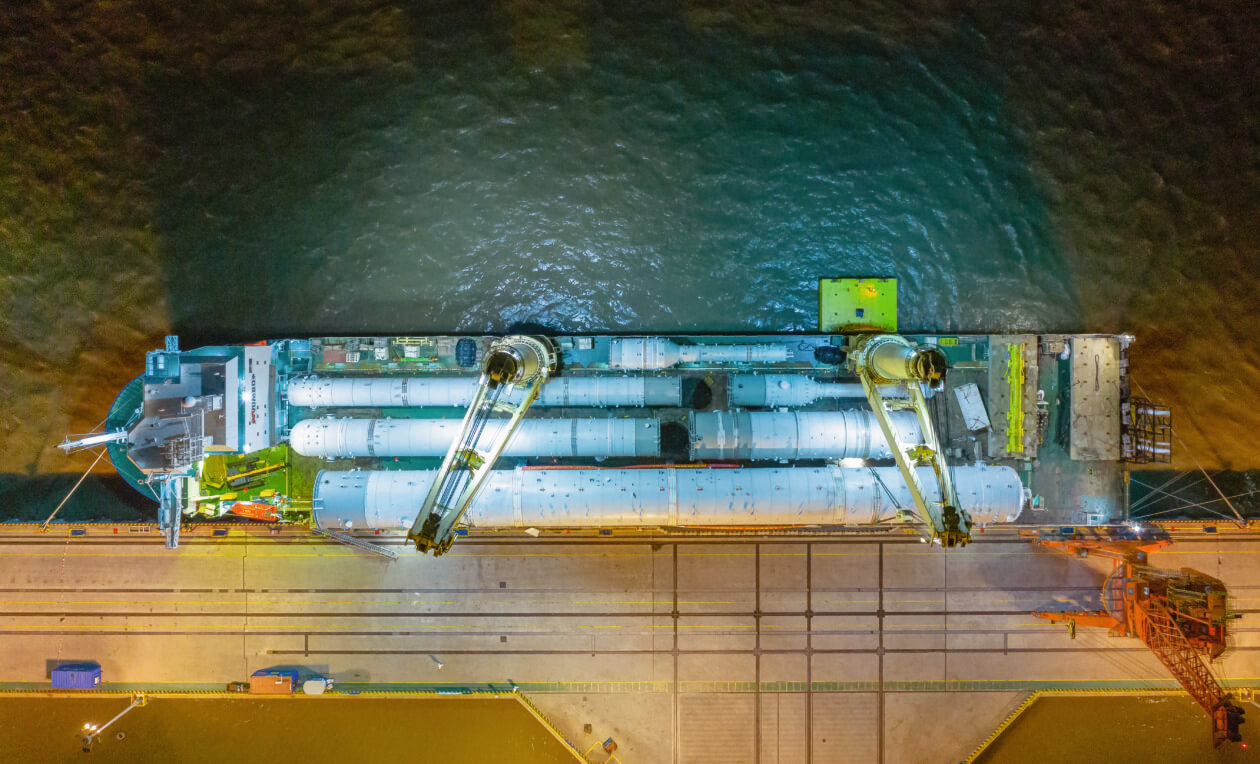

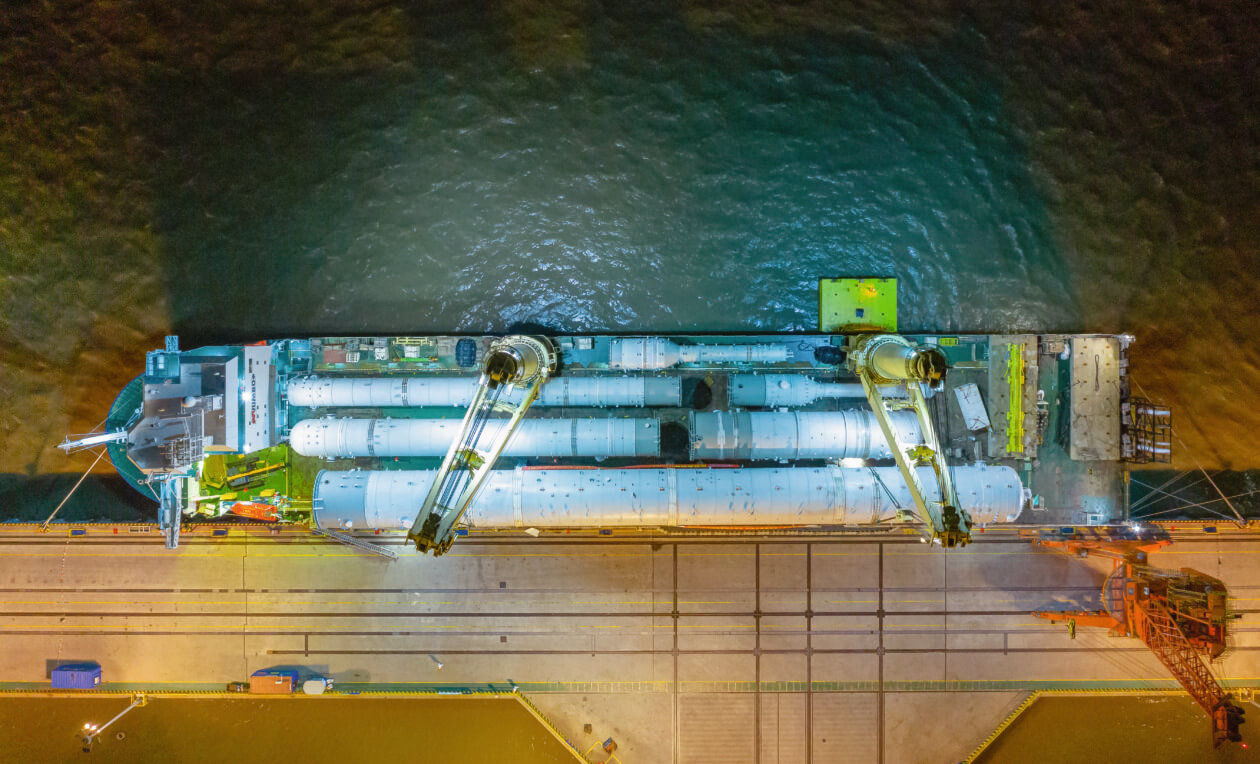

Cargo: Four 225.4 MT LNG storage tanks

Cargo dimensions: Each 48.93 x 5.8 x 6m long

Performance: On time, within budget and without any QHSES incidents

Challenges: Cargo movements through narrow streets of Decin’s City center

Water level: Strongly fluctuating river water levels

The deugro Difference

A key driver in deugro being awarded the contract was our proposal to utilize a self-propelled barge or modular carrier. This type of vessel has a low draft, allowing it to berth at the fabricator’s site jetty in Sekupang, Batam, Indonesia (which has a maximum depth of 5 meters at low tide).

To accommodate this jetty depth limitation, deugro Perth sourced the Dongbang Giant 5 from the specialized South Korean vessel operator Dongbang.

With an empty draft of 3.20 meters, the Dongbang Giant 5 could easily berth at the Sekupang jetty where, even after loading the two 650-metric-ton modules with a loaded draft of approximately 4 meters, there would still be sufficient and safe under-keel clearance from the seabed.

EPC Industry: Oil and gas

Shipping Period: August 2014 to July 2015

Cargo: 220 MT E-Room, 2x 650 MT modules and accessories

Volume shipped: 25,430 CBM, 1,674 MT

The Highlights

- Shipping through the Northern Sea Route

- Cargo weight of 860 MT, with a size of 39 x 18 x 35 m

- Over a period of four years, deugro transported 850,000 FRT in total from all over the world to Russia, China, Indonesia, the Philippines and Belgium.

- More than 17,500 single shipments, shipped by air, ocean and road, to various destinations around the world, including Sabetta in the Arctic North

- Eight sea voyages shipping a total of 98,350 cbm

- Additionally deugro shipped another 227,845 cmb, utilizing 24 sea voyages for other projects via the same NSR

Project Execution

More than 17,500 single shipments were shipped by all possible transportation modes, including air and ocean full charters, to various destinations around the world such as Sabetta in the Arctic North. A specialized heavy lift vessel was used together with ice breakers to ensure a safe passage. Along with experience gained dealing with local authorities to receive special permission, we have gained competence and know-how that not every project freight forwarder can offer.

Total Volume: 850,000 FRT, over 17,500 single shipments

Remote Location: Deep in the Russian Arctic

Global Project: Teams of over 10 countries involved

Project Duration: 4 years of planning and execution

Cargo Highlights: Heavy heater module, 860 MT, 39 x 18 x 35 m

Industry: Petrochemical

Cargo Highlight: 778.1 MT and nearly 100 m C3 tower

Volume: 280,000 FRT

Origins: Shipments from over 35 seaports and airports worldwide

Chartering: 155 breakbulk shipments on 55 chartered heavy lift vessels

deugro Team: Over 50 experts from 16 deugro country organizations worldwide

Industry: Petrochemical

On-carriage: Comprehensive transport engineering and civil works

Volume: 120,000 FRT

Weather Challenges: -17°C, heavy snowfall, ice and strong winds

Cargo Highlights: 889 MT and 96 m propylene-propane splitter

Performance: On time, within budget, without QHSES incidents

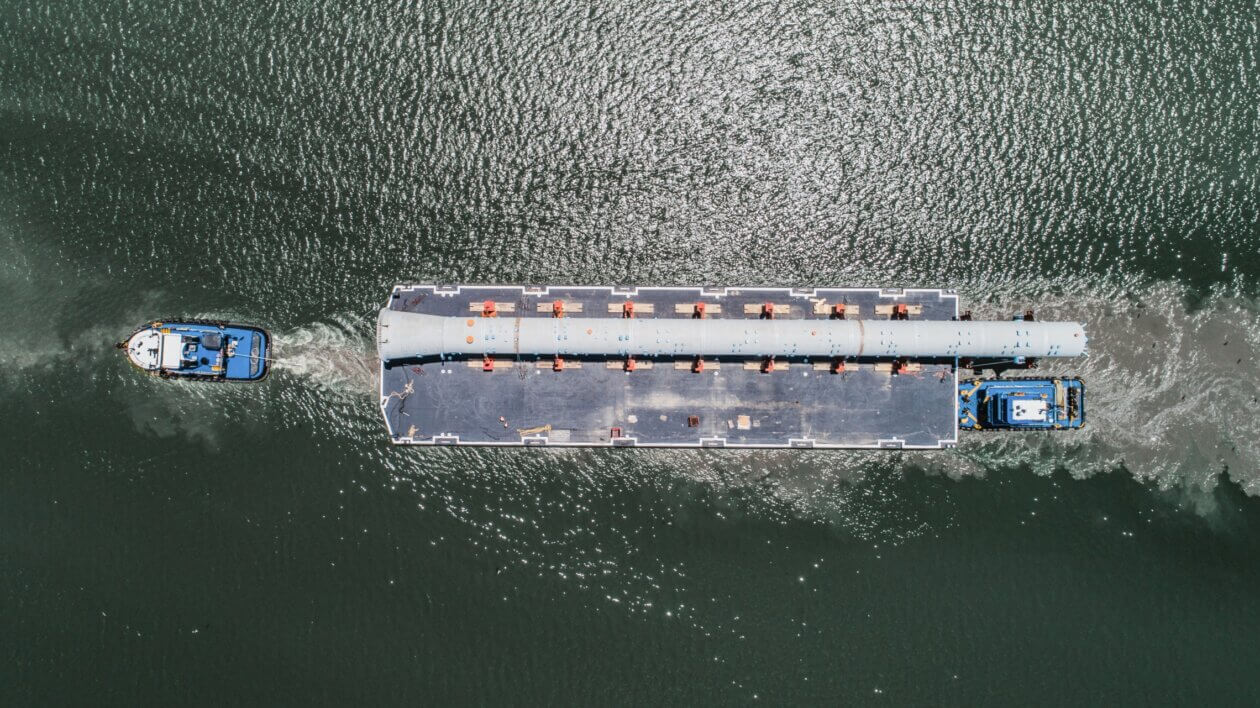

Industry: Petrochemical

Cargo Highlights: 81.93 m ethylene fractionator; 597 MT reactor

Volume: 35,541 FRT of industrial cargo

Timeline: Limited navigation period of max. three months

Route: Nothern Sea Route from South Korea via Tiksi to Ust-Kut, Russia

Coordination: High number of interfaces, barge voyages and overland trips

Project Challenges

- Because the C6 column hung over the barge’s stern by approximately 20 m – the trunnions to be lashed were above water.

- Cargo dimensions of up to 91.9 m in length and unit weights of over 485 MT

- Strict QHSES regulations in times of COVID-19

Industry: Petrochemical

Cargo: C6 column, lights tower, and primary fractionator

Total Weight: 967 MT of industrial cargo

Cargo Highlights: 91.9 m and 485 MT C6 column

Origin and Destination: From Ulsan, South Korea to Houston, Texas, USA

Performance: On time, within budget and without any QHSES incidents

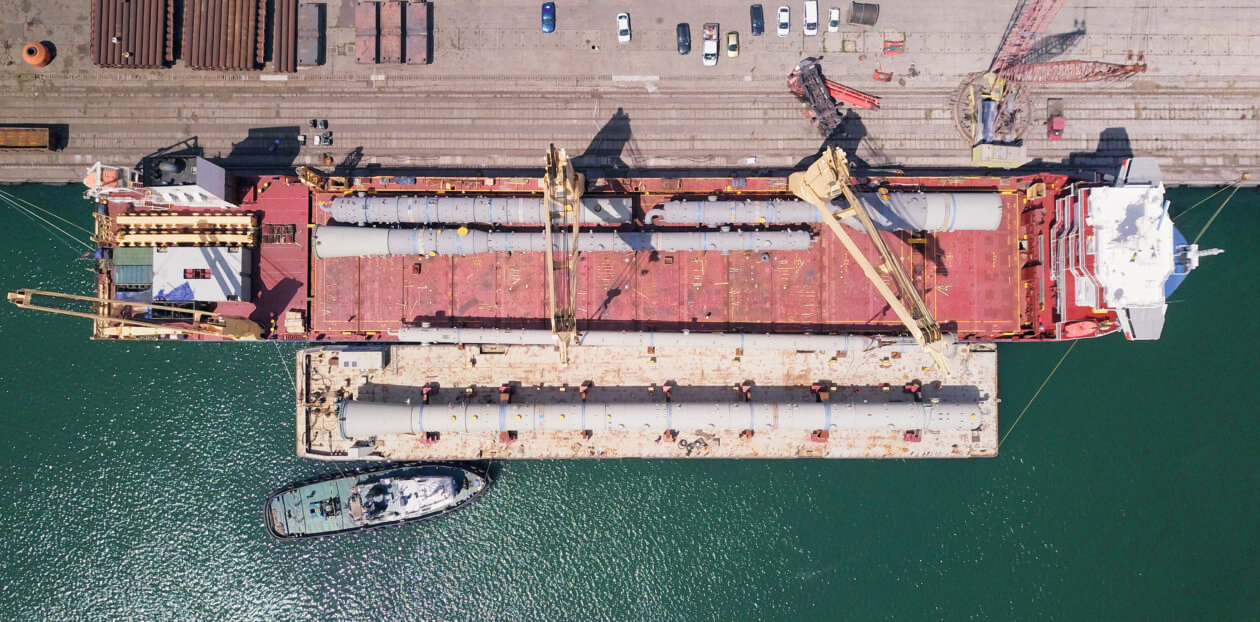

Industry: Petrochemical

Cargo Highlights: Primary fractionator (724 MT), C3 splitter (525 MT)

Volume: 87,350 FRT of heavy lift and oversized refining and processing equipment

Period: March-December 2020

Client: Linde Engineering

deugro Teams: 25 experts

Tobolsk is a town in Tyumen Oblast, Russia, located at the confluence of the Tobol and Irtysh Rivers, one of the most remote areas in Russia. It is a large industrial center in the field of gas chemistry, located in Western Siberia. The temperatures in winter fall to as low as minus 40 degrees Celsius and, when combined with icy winds, make working conditions extreme for all involved. In summer, the soil turns wet, which creates obstacles for any work on the ground.

Due to the intense weather conditions, deliveries are very difficult to perform. Heavy plant equipment can only be delivered via the Tobolsk waterways within a short navigational period of approximately 45 days between July and August. A delay of just a few days could result in the delivery being postponed to the next summer. To counteract the weather conditions, deliveries have to be meticulously planned, considering the construction schedule, delivery sequences, cargo readiness, opening of the navigational periods and, of course, the mobilization of the equipment such as barges and tugs.

Cargo Highlight: Two splitter units weighing 920 MT each, 106 m long

Total Volume: 261,000 FRT shipped for two contracts

Complex Transshipment Operations: On anchorage

Full charter: ~30,000 FRT carried in one single voyage

Tight Schedule: Matching short navigational time frames

Remote Ports Involved: Without landside infrastructure

Project Execution

Complete Set-up of a Fertilizer Plant in a remote Area of Tatarstan

Russia. A territory almost twice the size of the United States, or four times as big as the European Union.

A huge country with far-from-ordinary challenges and mega-projects requiring logistics solutions that are both complex and unique. For countries around the world, infrastructure is both an asset and a liability: an asset because it is the basis of all economic activity, but a liability because it must be maintained, updated, modernized and expanded.

This is no different in Russia, but infrastructure here is also subject to a number of additional challenges, such as the nation’s sheer geographical size as the world’s largest country and temperature variations in some regions of up to 60 °C between summer and wintertime.

Scope of Work

The overall scope consisted of ocean freight to Antwerp, interim storage and respective consolidation for on-carriage to the job site in Tatarstan, Mendeleevsk, involving all types of cargo, from container to overdimensional cargo, and heavy lifts up to 462 tons.

Various modes of transport were used, including ocean freight, air freight, road, rail and river sea vessel transport.

Volume: 850,000 FRT in total

42 Breakbulk and Heavy Lift Vessel Charters into Port of Sohar, Oman

Max. Heavy Lift: 1,230 MT, length up to 115 m

21,000+ Truck Movements to project sites

580+ Heavy Transportation Loads to project sites

Zero LTIs and Exemplary QHSES Performance

Industry: Petrochemical

Cargo: 811 CBM of urgent petrochemical equipment

Total Weight: 252 MT of industrial cargo

Cargo Highlight: 1,100 x 310 x 340 cm, 54.5 MT convection modules

Origin and Destination: From Italy and the Netherlands to Saudi Arabia

Schedule: 3 consecutive AN-124-100 air charter flights within just 7 days