deugro Successfully Delivers Over 25,778 CBM LNG Module to Deck Barge

Calgary, Canada, September 2, 2025 – As part of a major Canadian LNG project, deugro Canada, in close collaboration with deugro USA and the team from dteq Transport Engineering Solutions (dteq), successfully delivered a massive over 1,334-metric-ton and 38.3 x 31.6 x 21.3-meter module to a deck barge at the Port of Corpus Christi, Texas, USA.

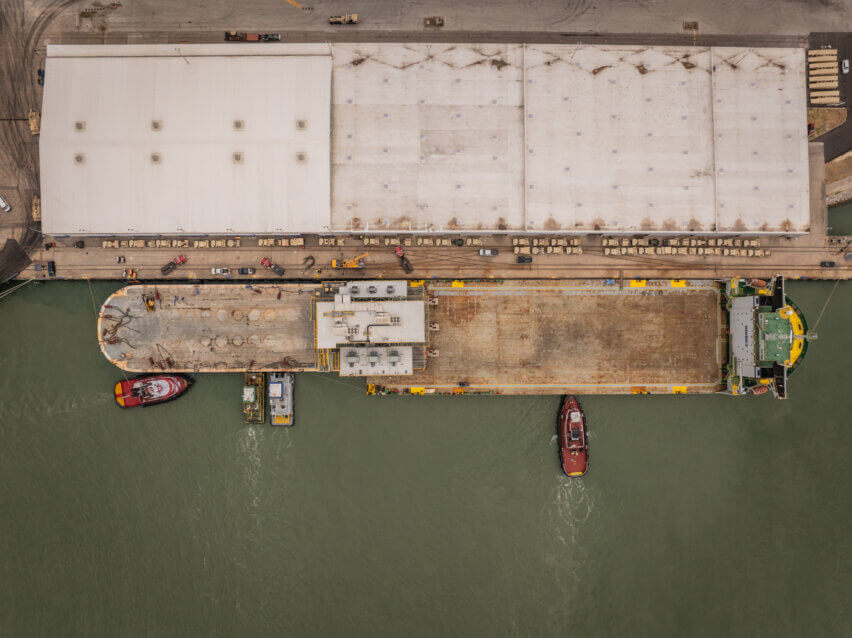

The oversized and heavy module was loaded out to barge at Port Ingleside, Texas, and transported to the Port of Corpus Christi. There, it was carefully loaded onto a deck carrier and securely fastened for its onward ocean journey. To ensure a safe barge voyage, the barge first had to be equipped with custom-designed grillage. Therefore, deugro, in close collaboration with dteq’s engineers, arranged for the delivery of the required grillage to the Port Aransas terminal in Texas, where it was installed onto the barge in accordance with dteq’s method statement and under the coordination and supervision of deugro and dteq personnel. Following the successful installation of the grillage, the dressed barge was moved to Port Ingleside, Texas. There, the LNG module was rolled onto the barge and positioned precisely in strict accordance with the method statements and the mooring plan developed and approved by dteq. After approximately 115 hours, loading and seafastening operations were successfully and safely executed.

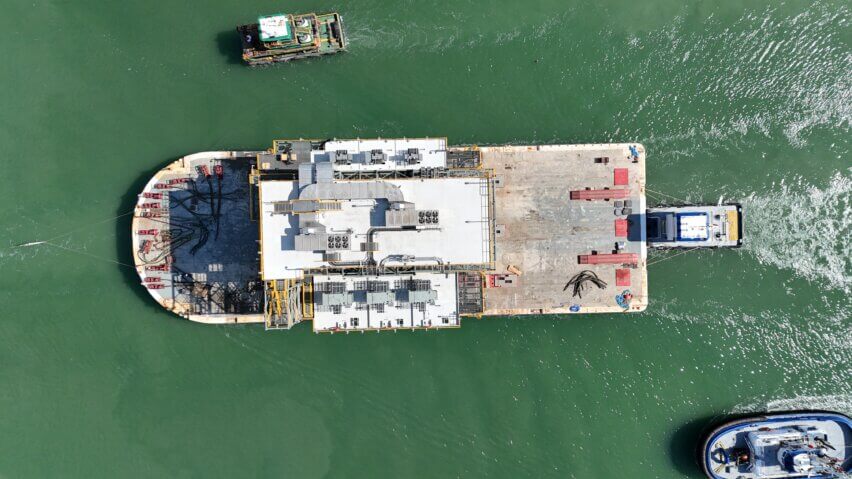

After arrival at the Port of Corpus Christi, the seafastening on the barge was removed so that the module could be carefully transferred to the deck carrier and maneuvered into the designated position by SPMTs for the sea voyage. As the movement of such sensitive, oversized and heavy cargo units from one floating object onto another floating object is always a critical operation, meticulous transport engineering and preparation as well as close communication and collaboration were of highest priority. Each step of the work had to transition precisely and seamlessly into the next. During the operations, altogether four tugboats were used to simultaneously keep the barge as well as the deck carrier in their required positions.

To ensure the safe transfer of the oversized and heavy module from the barge to the deck carrier, dteq’s engineers verified and recalculated the initial seafastening plans. This led to reduced overall operation times, reduced costs as well as higher operational efficiency for the client.

“The safe execution of this special move presented numerous challenges. Therefore, our engineering team worked relentlessly to jump multiple hurdles, including those that arose at the last hour. Starting with the seafastening design of the module, dteq optimized the securement for barge transport, enabling a timely arrival for the transfer from barge to deck carrier – Heavy Transport Vessel (HTV). This was followed by further optimization for the vessel itself, where dteq provided a revised seafastening plan that saved approximately 25% in time and material compared to the original plan,” said Franklin Alvarez, Regional Director Transport Engineering Americas at dteq USA.

“We provided full support to all teams involved and acted as a central connecting point to develop a hybrid mooring plan that considered both the vessel and the barge together, rather than analyzing them independently, for the transfer operation at the Port of Corpus Christi. dteq had boots on the ground to supervise and execute the plan, and to support the operations team from a technical and an operational standpoint,” Alvarez added.

The planning and execution were completed under increased pressure by a restricted operational time window due to the presence of US military vessels docked at the same pier during the loading and seafastening activities. At one point, the arrival of an additional military vessel required the relocation of the deck carrier to Port Aransas where all seafastening was finalized, requiring the swift mobilization of 27 welders to complete the works according to plan.

“Despite the complexity of the operation, the weight and the size of the module as well as the additional challenges, the excellent and close collaboration between deugro’s operations teams, the client, dteq’s transport engineers, our marine partners and all project stakeholders ensured that the module could be moved, loaded and seafastened onto the deck carrier according to schedule and budget—ready for setting sail to Canada,” said Antonio Garcia, Specialized Transport Manager at deugro USA.

“Executing this movement was truly a masterclass in coordination, resilience and precision. With tight timelines and high stakes, preparing the module for barge and ocean transport was a true test of precision logistics and engineering. From barge loading to final seafastening, every milestone was met with discipline, adaptability and teamwork. Proud to say: We secured, compliant and ready to sail,” said Lorna Green, Operations Manager at deugro Canada.