The power generation industry has evolved significantly over the last decade, with even more changes expected in the coming years. The energy transition—driven by government policies and rising demand for green energy—has reshaped the market. For deugro, this means adapting to new project sites, evolving equipment, and transport challenges. While coal-fired power plants once dominated energy production, the future lies in renewable and low-carbon energy sources.

Europe’s Green Deal, aiming for carbon-neutrality by 2050, and China’s target of achieving climate-neutrality by 2060, are key drivers of this transition. Europe operates around 270 coal-fired plants, while China has more than 1,000. Over the next 40 years, these plants will be gradually phased out. Global energy demand is expected to rise by 20% between 2020 and 2040, reaching 675 quadrillion BTUs, largely due to growth in developing economies.

Meanwhile, energy use in countries that are members of the Organization for Economic Co-operation and Development (OECD) is forecast to drop below 25%, driven by efficiency measures. A diverse energy mix of renewable and low-carbon non-renewables will be essential to meet this growing demand, as renewable energy remains vulnerable to natural fluctuations like sunlight and wind.

Gas-fired power plants, combined-cycle systems, and peaking plants will play a crucial role in stabilizing energy supply during high-demand periods. Technological advances in energy storage are also poised to revolutionize how energy is stored and used, helping to reduce reliance on real-time generation. The shift toward smaller, decentralized power production is also evident, with interconnectors becoming essential to balance energy supply across regions.

Peaking power plants and grid synchronizers, particularly in Europe, North America and Australia, are emerging as key solutions during peak electricity demand. These plants can ramp up quickly, going from standby to full power in under 15 minutes, making them critical for grid stability. Fast-track schedules for smaller projects further challenge logistics, with reduced planning and execution timelines for permitting, bridge assessments, and equipment mobilization.

In South America, the Far East and Southeast Asia, large-scale power plant projects continue, focusing on replacing outdated coal-fired plants. In Europe and North America, attention has shifted to brownfield upgrades, to converting coal plants to gas or to upgrading existing gas plants to be in line with the latest technological standards. The industry’s rapid evolution brings along with it a diverse range of logistical challenges, particularly at modern, space-limited power plant sites. Precise planning is required to move critical components, with early engagement of experienced project freight forwarders essential for project success.

As part of the Jawa-1 Power Plant Project, deugro transported approximately 80,000 freight tons of cargo, including two 435-metric-ton gas turbines, two 460-metric-ton generator stators, and 52 heat recovery steam generators (HRSGs) with a length of up to 30 meters and weights of up to 240 metric tons. The cargo originated from Asia, Europe and the USA, with one gas turbine traveling over 8,550 nautical miles from Antwerp through the Suez Canal to Indonesia.

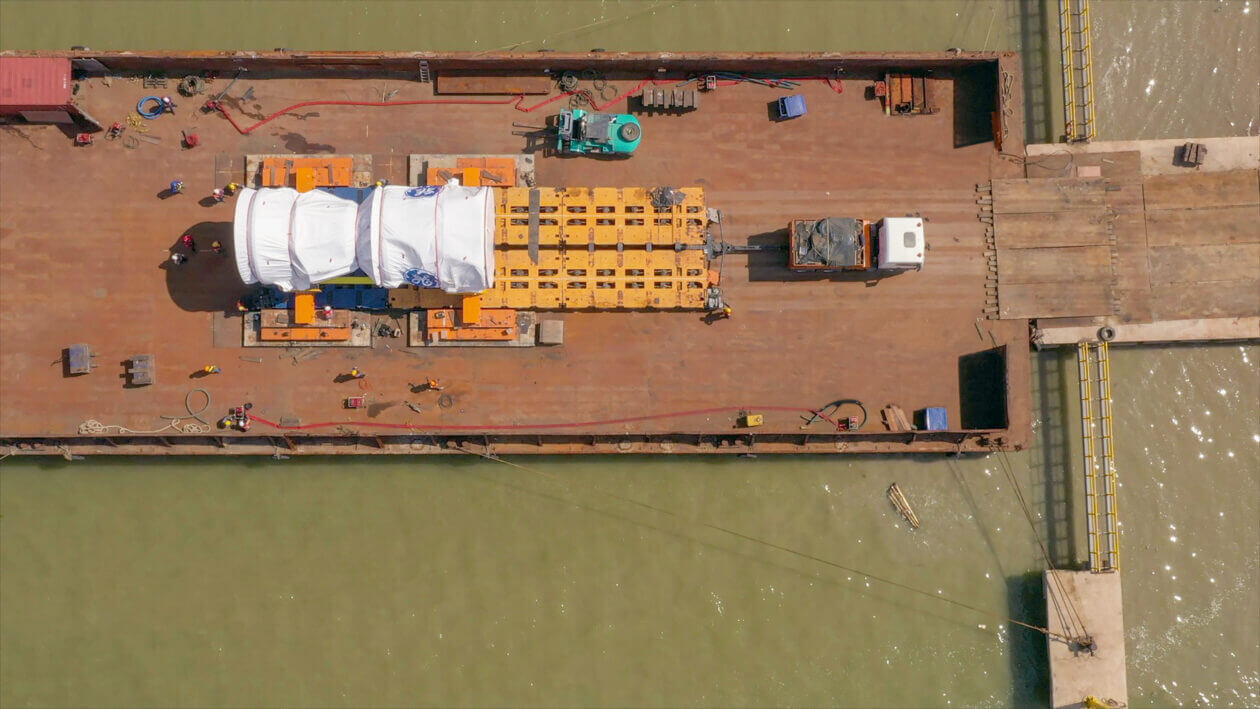

A major logistical challenge involved the direct unloading of oversized components onto barges at the Port of Tanjung Priok and then safely transporting them through small villages with little space to maneuver. deugro implemented a direct discharge system at the port, transferring the cargo directly from the vessel to the barge, eliminating the need for double-handling and reducing costs and risks. The deugro team conducted detailed route surveys to safely navigate the narrow roads and villages, ensuring a smooth seven-kilometer journey along a purpose-built roadway to the construction site.

The Jawa-1 Power Plant is projected to supply electricity to around 4.3 million Indonesian households. This 1,760 MW liquefied natural gas (LNG)-powered combined-cycle gas turbine (CCGT) facility is designed to address Indonesia’s growing energy needs while supporting the country’s target of 100% electrification by 2024.

As one of the largest gas-fired power plants in Southeast Asia, Jawa-1 showcases advanced efficiency through its combined-cycle technology, which captures waste heat from the gas turbines to generate additional electricity. This design not only boosts efficiency but also significantly cuts emissions compared to older coal-fired plants, playing a key role in Indonesia’s transition to cleaner energy sources.