deugro Successfully Executed the NKNK03 Olefin Project on Behalf of Linde Engineering

deugro has moved 90,000 freight tons of heavy lift and oversized cargo from various origins in the Far East and Europe to a remote job site in Nizhnekamsk, Republic of Tatarstan, Russia.

After detailed project planning and engineering preparation, the project execution started on schedule. The volume of the project encompassed more than 300 heavy and oversized units of valuable refining and processing equipment. These included a 724-metric-ton primary fractionator measuring 78 x 9.8 x 9 meters as well as a 525-metric-ton C3 splitter measuring 96 x 7 x 6.9 meters.

deugro’s team of experts developed a tailor-made transport solution for this challenging petrochemical project. They had to consider a complex logistics schedule with short navigation periods and a challenging passing of the winding Don River and Volga–Don canal to reach the remote location of the naphtha cracker in Nizhnekamsk.

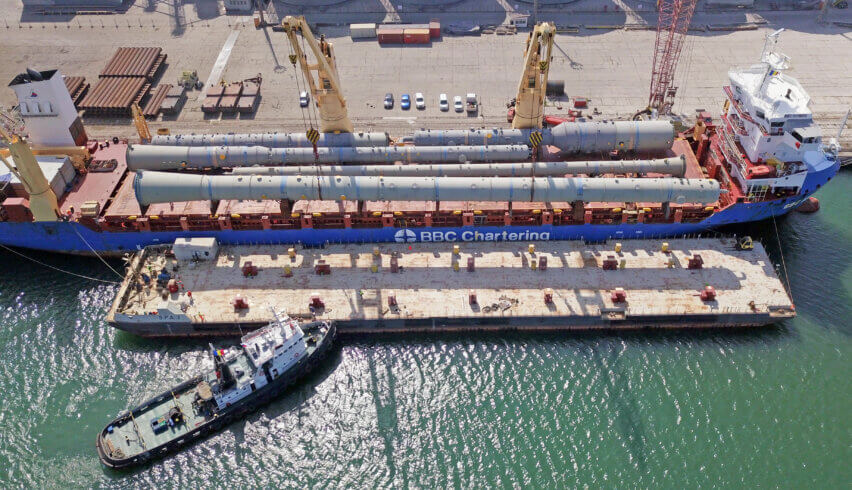

The entire cargo was transported by a total of nine full-charter vessels. However, given the cargo specifications and total volume, only a limited number of heavy lift vessels were available in the market to complete these voyages.

The heavy lift and overdimensional pieces were shipped from various international seaports to the Nizhnekamsk jetty (dry dock and Transkama Port) in the Russian Federation.

For the cargo originating from the Far East, including the heaviest and largest cargo units, the Port of Constanta in Romania was chosen as strategic transshipment hub. In Constanta, unloading was executed from the ocean-going vessels directly onto a total of 11 barges and various sea river vessels.

Safe loading and passing of the Don River and Volga–Don canal required detailed preparation. After stowage of the sensitive cargo, the barges started their journey of over 1,350 nautical miles to their destination, the dry dock in Nizhnekamsk.

Once the LOAD-IN was executed, under continuous supervision of a ballast engineer, the Self-Propelled Modular Trailers (SPMTs), which together with the cargo measured over 10 meters in height, were ready for the 21-kilometer on-carriage move to the site, accompanied by escort cars and the local traffic police. Afterwards, the empty SPMTs returned to be ready for the next unit roll-off the following day.

“To ensure smooth road transportation, especially for the heavy lift pieces, many obstacles such as fences and overhead obstructions, including high-voltage power lines, rotaries and traffic lights, had to be dismantled or improved. During the project peak, we coordinated over 100 axles of SPMTs operating in Nizhnekamsk. deugro Moscow was always on hand supervising the journey to the job site in Nizhnekamsk every step of the way,” said Pavel Sinitsyn, Project Manager, deugro Projects LLC (RUS).

More than 300 additional cargo parts were unloaded at the Port of Transkama and transported overland to the construction site. Due to the short navigation time in which the entire cargo had to reach Nizhnekamsk, every step of the transport chain had to run precisely like clockwork. The successful and safe completion of this extensive project is due to the excellent cooperation with our clients, the project owner and our partners.

“Already at the early stage of the project, it was obvious that the transportation of heavy lift components would be an enormous challenge on many different levels. This included not only the sheer number of heavy lift items to be transported during the limited navigation window for river transportation, but also the extremely demanding “Last Mile Transport” which was characterized by a complex ownership structure of infrastructure obstacles and certain conflicts of interest.

“And at that time, no one could have foreseen the additional difficulties caused by the global COVID-19 pandemic.

“However, thanks to the great cooperation between the deugro and Linde project teams, the transportation of all heavy lift and oversized components was a complete success and all the cargo was delivered to the receiver Nizhnekamskneftekhim, on time and without damages.

“The Linde team would like to take this opportunity to express their sincere appreciation to deugro and its partners for their demonstrated willingness to work constructively and their obvious pleasure while mastering the various logistical challenges,” said Frank Graßl, Project Logistics Manager, Linde GmbH, Engineering Division.